International Conference on High Quality Special Steel 2022 &6th Academic Conference on Special Metallurgical Technology, organized by The Chinese Society for Metals (CSM)and Northeastern University (NEU),was successfully held from August 18 to 21, 2022 in the NEU International Hotel in Shenyang, China. Considering the COVID-19 pandemic around the world, this event was on-site communication combined with on-line presentation (by zoom meeting). The chairmen of this conference were Prof. Zhouhua Jiang (Northeastern University, China) and Prof. Rong Zhu (University of Science and Technology Beijing, China).

With more than one year preparation, 69 manuscripts were published in the conference proceedings after peer-reviewed by the technical committee. The topics of this conference covered research and development of high quality special steels & special alloys and special metallurgy technology of high-end special steels. 8 plenary lectures, 18 keynote presentations and 17 contributed presentations were arranged, more than 300 participants from 10 countries attended this event.

Group photo of attendeesin China

Opening ceremony of the conference

26 well-known expertswere invited to give the keynote speechin the fields of special metallurgical technology.

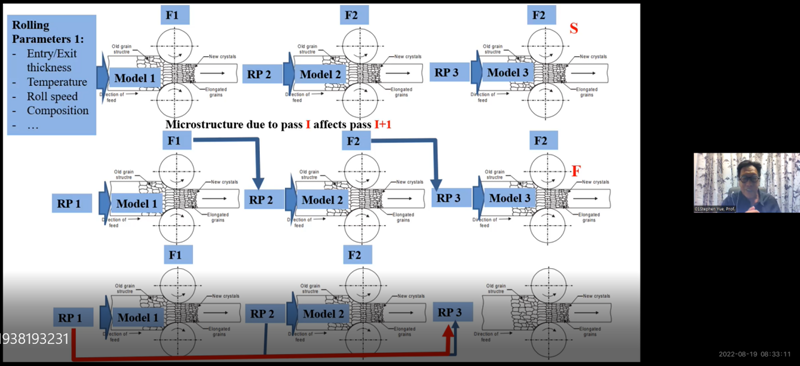

1. Prof.Stephen Yue, McGill University, Canada

Prof.Yue gave a keynote speech entitled "Machine Learning Applied to the Hot Rolling of Steel", and introduced the control model of hot rolling process, especially the application of machine learning in rolling process and its influence on the microstructure, element distribution and properties of subsequent rolled products. Finally, Prof.Yue pointed out that the application of artificial intelligence such as machine learning in metallurgy is an important development direction in the future.

2. Prof.HanDong, Shanghai University, China

Prof.Han Dong gave a keynote speech entitled "Exploration of High Performance of Iron and Steel Materials". Prof.Han Dong analyzed the demand of social development for steel materials, and introduced the effects of purification and alloying on the properties of materials as well as the properties and development trend of pure iron, soft magnetic and ultra-high strength steels. He also introduced the influence law of rare earth on improving the purity and properties of high-end special steels, especially the beneficial effect of rare earth on the corrosion resistance of steels. Finally, he put forward the path of adopting green steel to realize the goal of double carbon in steel industry.

3. Prof. Olexandr Velychko, National University of Ukraine, Ukraine

Prof. Velychko gave a keynote speech entitled "Technologies of gas-oxygen refining-multifunctional options for smelting stainless steel and ferroalloys". He pointed out that gas-oxygen refining (GOR) technology is an efficient method for smelting stainless steel and refining ferroalloy, and has been successfully applied to the matching refining of 3-80 tons converter process.

4. Prof.MenghuaiWu, Leoben University, Austria

Prof.Menghuai Wu gave a keynote speech titled "Advanced Process Simulation of Solidification and Remelting", focusing on the advanced simulation technology of smelting and solidification process. Prof.Wu introduced the metal crystallization behavior at macro and micro scales during metal melting and solidification, systematically introduced the growth models of single-phase, 2-phase and 3-phase mixed dendrites and equiaxed grains, and introduced the process models of electroslag remelting, vacuum arc remelting and rapid electroslag remelting.

5. Prof.Jong-Jin Pak, Hanyang University, Korea

Prof.PAK gave a keynote speech on Inclusion Thermodynamics for High-Mn and High-Al Advanced High Strength Steels. The effects of different chemical elements on N dissolution and AlN formation in high Mn-Al steels were measured by metal-nitride-gas equilibrium method, and the kinetics of N, O and inclusion formation in high alloy steels predicted by new database and model were evaluated.

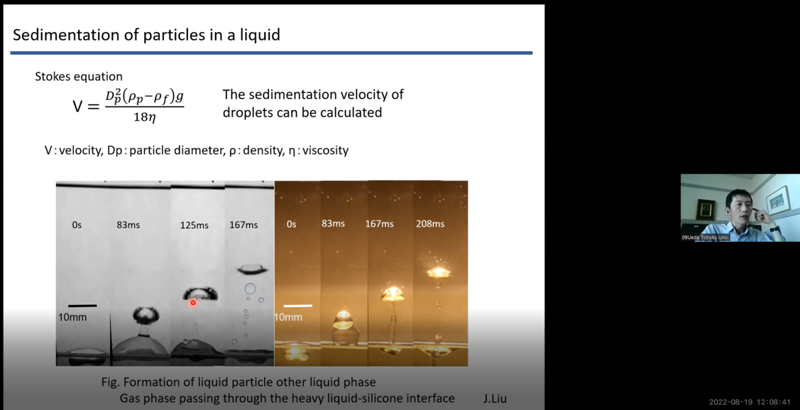

6. Prof.Ueda Shigeru, Tohoku University, Japan

Prof.Shigeru gave a keynote speech entitled "Physical properties of slag to promote reaction and separation of slag and metal". Prof.Shigeru analyzed the influence of liquid slag and metal particle properties on the "gas-slag-gold" reaction process in steelmaking process by experimental research method.

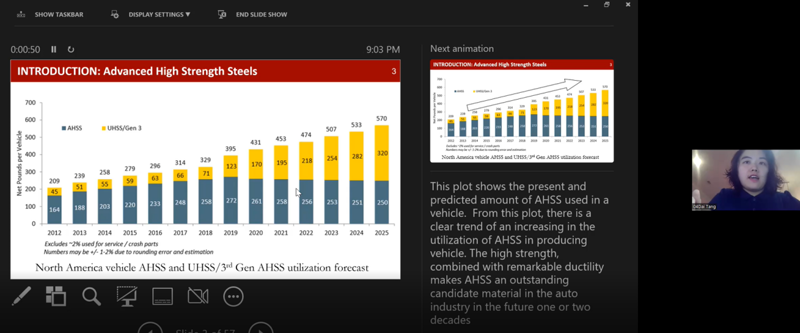

7. Dr. Dai TANG, Georgia Institute of Technology, USA

Dr. TANGgave a keynote speech entitled "Nitrogen control in production 3rd AHSS steel", systematically introduced the development demand of ultra-high strength steel and the composition, microstructure and performance characteristics of the third generation ultra-high strength steel, and systematically introduced the control of N content in ultra-high strength steel and its role.

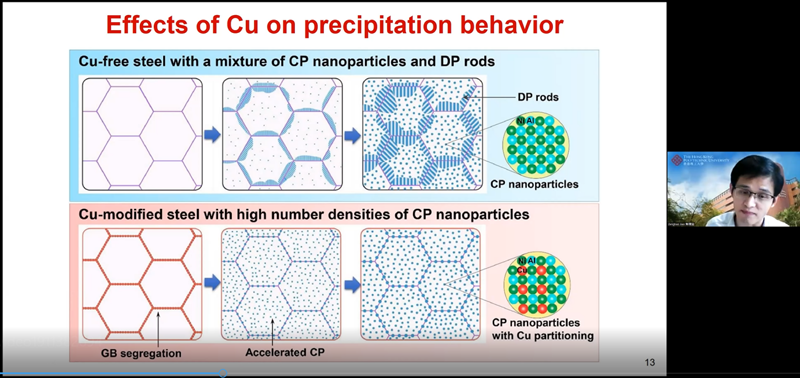

8. Dr. ZengbaoJiao, Hong Kong Polytechnic University, Hongkong, China

Dr. Jiao gave a keynote speech entitled "Control of continuous and discontinuous precipitation in advanced high-strength steels", introduced the mechanism of continuous and discontinuous precipitation in high-strength steels, and systematically introduced the role of Cu in high-strength steels. The results show that Cu can promote continuous precipitation of strengthening phases and inhibit discontinuous precipitation.

9. Dr. Hiroshi FUKAYA, Japan Steel Works, Japan

Dr. FUKAYA gave a report on "Measurement of the Al deoxidation equilibrium and its application in the operation for high cleanliness steels", discussed his research on Al deoxidation equilibrium of Fe-Ni alloy and Fe-Cr-Ni alloy at 1500 ℃ and 1600 ℃, and predicted the thermodynamic conditions for the formation of secondary inclusions at low temperature.

10. Prof.In-Ho JUNG, Seoul National University, Korea

Prof.JUNG gave a report entitled "Thermodynamic and viscosity database for ESR slags: Design of ESR slag chemistry", introduced the thermodynamic and viscosity database of ESR slag system, and pointed out a systematic method to design the ratio of ESR slag system according to alloy composition, smelting process and other parameters.

11. Prof.Lev Medovar, Barton Electric Welding Research Institute, Ukraine

Prof.Medovar gave a report entitled "About place of desulphurization at ESR". He analyzed the kinetic conditions of desulfurization reaction in ESR process, introduced the application of liquid pouring and rotary ESR process, and compared the droplet behavior with traditional ESR process.

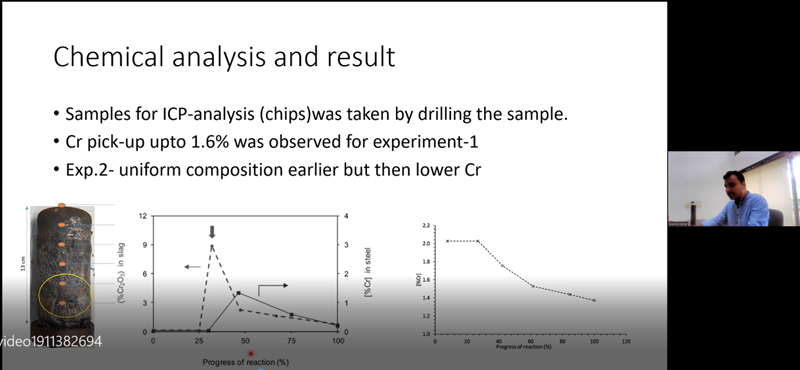

12. Dr.Depoo KUMAR, Indian Institute of Technology, India

Dr.KUMAR gave a report entitled "Exchange of metals between slag pool and steel droplet during ESR remelting process". Through experiments, the morphological changes of metal droplets during slag-gold transformation in ESR process were studied, and the influence of Cr2O3 content in slag on remelting process was studied.

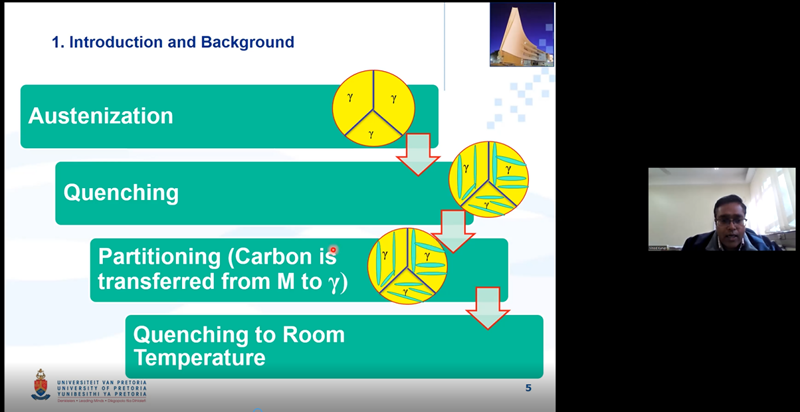

13. Prof.V Kurup Charles SIYASIYA, University of Pretoria, South Africa

Prof.SIYASIYA gave a special report entitled "Fluence of quench and partition heat treatment on the transformation kinetics of high aluminum steel", introduced the influence of quenching and partition heat treatment process on high aluminum steel, and analyzed the precipitation behavior of C, Al and other elements in high aluminum steel theoretically.

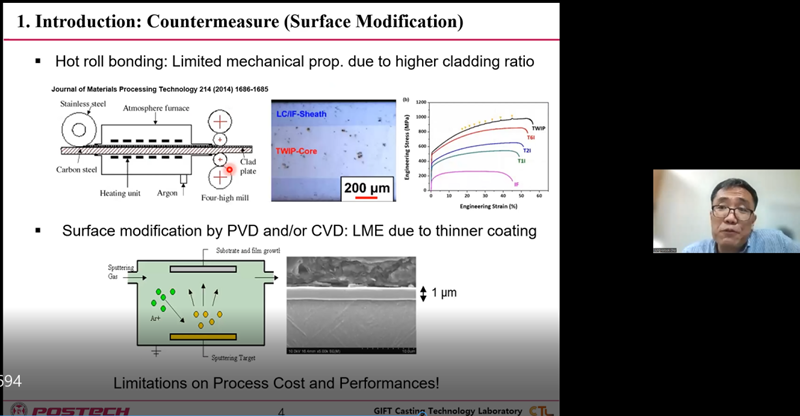

14. Prof.Jung-wook CHO, Pohang University of Science and Technology, Korea

Prof.CHO gave a special report entitled "Surface modification of high-Mn steel to reduce hot crack susceptibility by formation of functionally graded interlayers". Prof.CHO adopted the method of forming special layer structure at phase interface to control the internal structure of high manganese steel, thus inhibiting the hot cracking tendency of high manganese steel and providing a new idea for hot cracking control of high manganese steel.

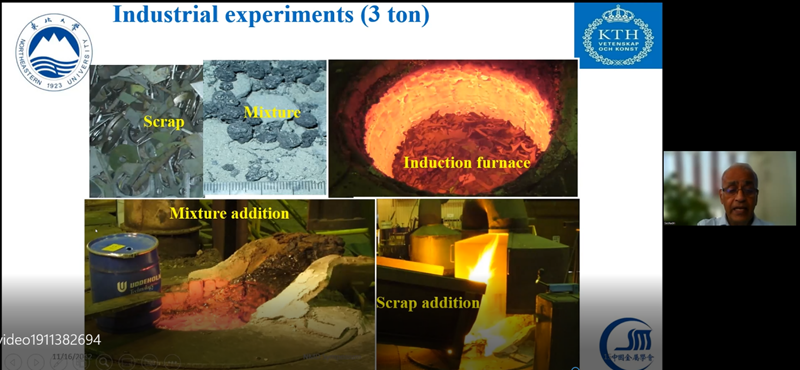

15. Prof.Seshadri SEETHARAMAN, Royal Swedish Institute of Technology, Sweden

Prof.SEETHARAMAN gave a special report entitled "Mo, Cr and V alloying in special steels", introduced the global reserves and utilization of Mo, Cr and V, and discussed the new alloying methods of Mo, Cr and V as well as the experimental results.

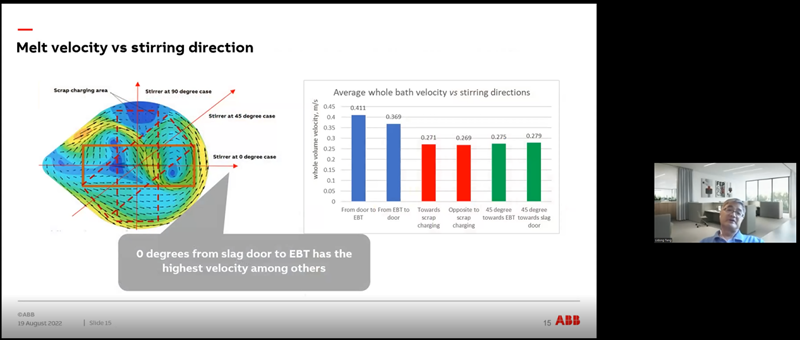

16. Dr. Lidong Teng, ABB Metallurgy, USA

Dr. Teng gave a special report on "Effect of electrical stirring on stainless steel smelting process in an electrical arc furnace", introduced the role of electromagnetic stirring in electric arc furnace smelting process, and introduced the new electromagnetic stirring technology of "Arcsave".

17. Prof.ZhouhuaJiang, Northeastern University, China

Prof.Zhouhua Jiang focused on the theme of "New Progress of Electroslag Metallurgy Technology". He systematically introduced the development history of electroslag metallurgy technology at home and abroad, the basic characteristics and theoretical basis of the new generation electroslag remelting technology including inclusion control theory in electroslag remelting process and solidification quality control of electroslag remelting ingot, as well as the innovation and development of new ESR technology including high clean and high homogeneity ESR technology and equipment, extra thick slab and extra large ingot ESR technology, semi-continuous ESR solid and hollow ingot ESR technology and equipment, ESR energy saving technology, etc.

18. Prof.JingLi , University of Science and Technology Beijing, China

Prof.Jing Li focuses on the theme of "in-situ transformation technology of eutectic carbide in high carbon martensitic stainless steel". The size and distribution of eutectic carbides in ESR high carbon martensitic stainless steel as-cast and after hot working were studied by means of theoretical calculation and experimental observation. The effective measures to improve the solidification structure and mechanical properties of ESR ingot were discussed.

19. Prof.Guangqiang Li, Wuhan University of Science and Technology, China

Prof.Guangqiang Li took "Research on Purification of Electrolytic Manganese Metal by Electroslag Remelting" as the theme, and effectively improved the removal efficiency of sulfur and oxygen elements in manganese metal by using Na2O-containing slag system, adding magnesium-calcium deoxidizer, regulating the holding time and smelting atmosphere of electroslag remelting. At the same time, the distribution of sulfide inclusions and residual sulfur content in electroslag ingot at ingot height was systematically discussed.

20. Dr. JinguoLi , Institute of Metals, Chinese Academy of Sciences, China

Dr. Jinguo Liintroduced "Research on Preparation Technology of High Purity Homogeneous Superalloy". The purification control of superalloy was realized by master alloying + purification of active elements and rare earth + melt refining treatment, crucible material selection and filter residue retaining device. Accurate composition control was realized by rapid analysis in front of furnace + precise feeding + process control, and homogenization control was realized by high temperature melt treatment + electromagnetic stirring. In addition, the control of metallurgical defects and remelting microstructure and properties of master alloy was systematically introduced.

21. Prof.Yunbo Zhong, Shanghai University, China

Prof.Yunbo Zhong gave a report entitled "Research Progress and Thinking of Magnetically Controlled Electroslag Remelting Technology". By means of numerical simulation and physical experiment, the influence of magnetic field on the evolution of metal droplets, the removal mechanism of inclusions, the solidification quality of ESR ingot and the control measures were discussed, providing a new method for the preparation of high homogeneity and high purity ESR ingot.

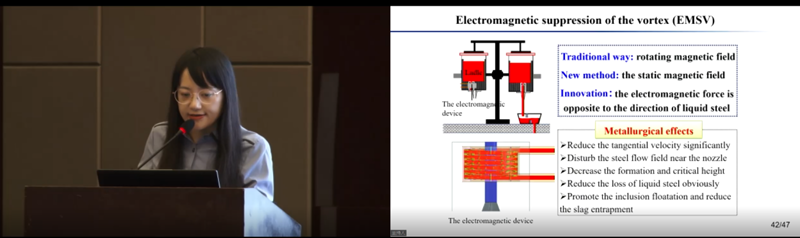

22. Dr.Xiaoming Liu, Northeastern University, China

Dr.Xiaoming Liu gave a special report entitled "Research progress of new electrical metallurgy technologies in continuous casting process", and systematically introduced the application of new electromagnetic metallurgy technology in continuous casting process from the perspectives of theoretical research, numerical simulation technology, industrial test and application.

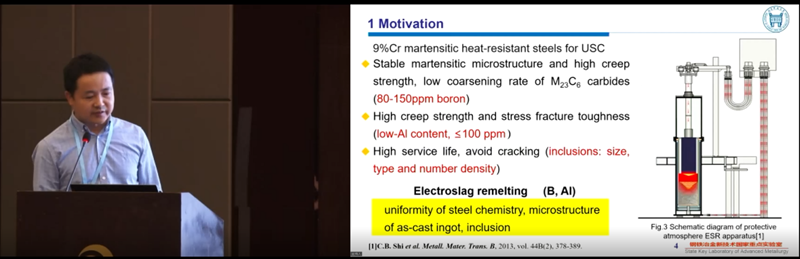

23. Dr.ChengbinShi, University of Science and Technology Beijing, China

Dr. Chengbin Shigave a special report entitled "Active Element Variation and Inclusion Evolution During Electro-slag Remelting of a Heat-Resistant Steel for Ultra-supercritical Power Plants", and analyzed the evolution process of inclusions in the electroslag remelting process of ultra-supercritical energy steel.

24. Mr. Zhicheng Zhang, Daye Special Steel Co., Ltd., China

Mr. Zhicheng Zhangmade a report on "Building Digital Intelligence to Help the High-quality Development of Special Metallurgical Products of Daye Special Steel", and systematically and comprehensively introduced the special alloy materials and special smelting equipment of Daye Special Steel, the current situation and development trend of special metallurgical industry at home and abroad, and the exploration and application of digitalization and intelligence in the preparation process of high-quality special metallurgical products.

25. Mr. Yu Teng, Fushun Special Steel, China

Mr. Yu Tengmade a report on Types, Causes and Control of Metallurgical Defects in Vacuum Arc Remelting of Superalloys. The causes of forming defects such as radial black spot, axial black spot, dirty white spot, clean white spot, discrete white spot, dendrite white spot and solidified white spot are analyzed in depth. The hazards of various metallurgical defects are introduced, and the three stages of VIM, ESR and VAR are studied respectively, and the effective measures to prevent metallurgical defects in each stage are discussed.

26. Dr. CandongZhou, China Baowu Steel Group Corporation, China

With the theme of "Research and Development of Special Stainless Steel in Baowu Special Metallurgical Industry", Dr. Candong Zhou introduced the materials and products of special stainless steel for nuclear energy, high-grade gas valve steel/alloy, high pressure boiler tube G115 steel, blade steel, special stainless steel for aerospace and hot-rolled cold-rolled plate series of Baowu Special Metallurgy Company, and compared with the advanced level at home and abroad in an all-round way.

During the conference, the tremendous progress of special steel and special metallurgy technologyin the past years was reviewed; the latest scientific and technological progress was exchanged. The feedback from the delegates were positive, most of them have benefited much from their participation in this conference. The next conference will be held in China in 2024.